Automotive Quality Control and the Critical Role of Advanced Gaging Systems in Manufacturing

Charlotte, United States - December 10, 2025 / F D Hurka Metrology /

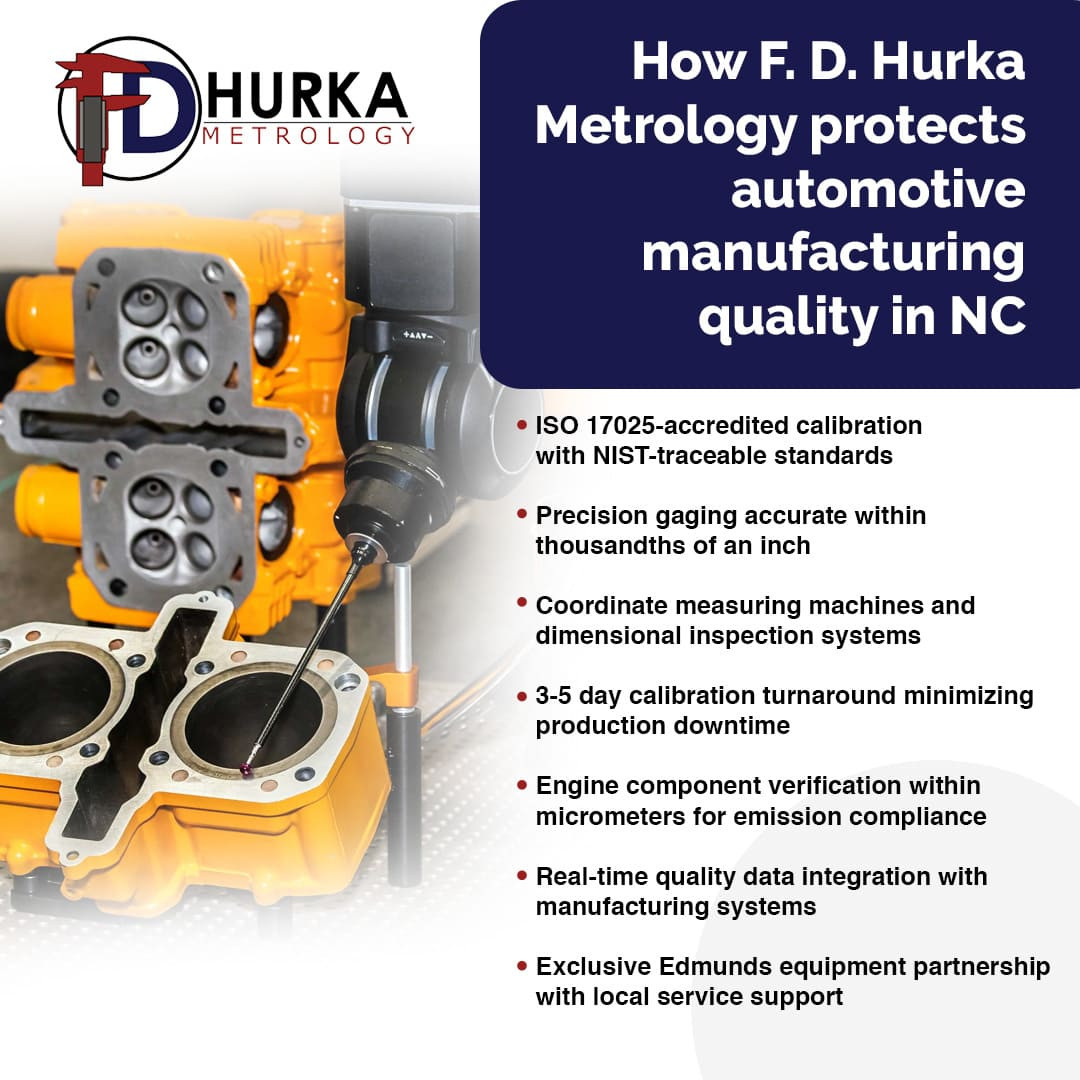

Charlotte, NC – F. D. Hurka Metrology continues to serve North Carolina's automotive manufacturing sector with advanced measurement solutions that prevent quality failures and production disruptions. The Charlotte-based company provides automotive quality control gaging systems in North Carolina that help manufacturers maintain strict quality standards while avoiding costly recalls.

Manufacturing defects in the automotive industry create substantial financial losses through production delays, warranty claims, and brand damage. F. D. Hurka Metrology addresses these challenges through precision measurement equipment and calibration services that detect problems before they reach consumers.

Precision Gaging for Automotive Manufacturing in NC Prevents Costly Failures

The company's precision gaging for automotive manufacturing in NC includes coordinate measuring machines, dimensional inspection systems, and electronic gaging equipment. These systems verify component specifications throughout the production process, from engine parts to safety-critical components.

Automotive manufacturers require measurement accuracy within thousandths of an inch to meet industry standards. F. D. Hurka Metrology's gaging systems catch defects early in production cycles, preventing expensive rework and maintaining production schedules.

Engine components demand extreme precision for proper function and emission compliance. Cylinder bores, valve seats, and crankshaft journals require measurement within micrometers. Transmission gears need accurate tooth profiles and spacing. Brake system components undergo rigorous dimensional inspection to prevent safety failures.

Automotive Metrology Solutions in Charlotte Support Regional Manufacturing

F. D. Hurka Metrology's automotive metrology solutions in Charlotte provide local support advantages that minimize production disruptions. Quick response times and on-site calibration services reduce equipment downtime for regional manufacturers.

The company maintains ISO 17025 accreditation and NIST-traceable standards through its advanced calibration facility. Their 3-5 day calibration turnaround time keeps automotive production lines operating smoothly while maintaining measurement accuracy.

President Chuck Meredith leads the company's customer-focused approach with over 25 years of industry experience. The team combines decades of measurement expertise with modern calibration capabilities to address diverse automotive measurement requirements.

Key Service Areas Include:

Equipment calibration with ISO 17025 accreditation and NIST traceability

Precision measuring tool sales and technical consulting

On-site calibration services and rapid turnaround times

Training programs for measurement techniques and data interpretation

Gaging Systems for Auto Industry Services Meet Evolving Technology Demands

Modern gaging systems for auto industry services integrate with manufacturing execution systems and enterprise resource planning platforms. This integration provides real-time quality data and automated reporting capabilities that improve production efficiency.

F. D. Hurka Metrology stays current with industry trends as automotive manufacturing evolves toward electric vehicles and autonomous systems. These technologies create new measurement challenges that require different approaches than traditional automotive components.

The company's exclusive partnership with Edmunds brings advanced gaging equipment to manufacturers across nine territories. This relationship combines Edmunds' manufacturing excellence with local service capabilities and responsive technical support.

Advanced Automotive Metrology Solutions Address Industry Standards

Automotive metrology solutions must comply with strict safety and quality standards, including ISO/TS 16949 requirements and Federal Motor Vehicle Safety Standards. F. D. Hurka Metrology provides calibration certificates and traceability documentation that satisfy audit requirements.

Digital gaging systems offer statistical process control integration that identifies trends and variations in manufacturing processes. Real-time measurement feedback allows operators to adjust processes before defects occur, while historical data reveals equipment wear patterns.

The company serves automotive manufacturers throughout North Carolina with equipment selection, calibration services, training, and ongoing technical support. Their industry-specific expertise helps clients implement effective quality control programs that improve production efficiency.

Proven ROI and Partnership Success Drive Industry Growth

Founded in 1972, F. D. Hurka Company has built long-term partnerships with automotive manufacturers by delivering consistent results and exceptional service quality. Their facility houses advanced calibration equipment capable of handling the most demanding automotive measurement applications.

Quality improvements through proper gaging systems generate substantial returns through reduced scrap, rework, and warranty costs. Prevention of a single major quality incident often justifies entire gaging system investments while protecting brand reputation.

Ready to Improve Your Quality Control?

Contact F. D. Hurka Metrology today to discuss automotive measurement needs and discover how their proven gaging systems can improve quality control processes while maintaining competitive production costs.

Contact Information:

F D Hurka Metrology

4731 Stockholm Ct

Charlotte, NC 28273

United States

Charles Meredith

https://www.fdhurka.com/

Original Source: https://www.fdhurka.com/quality-control/automotive-quality-control-and-the-critical-role-of-advanced-gaging-systems-in-manufacturing/